La Garde is a provincial town in the Var department near to Toulon that is a mix of modernity and tradition. It sees itself as a caring town and is proactive when it comes to its residents’ wellbeing, which is why it decided to build the Marie Curie 2, a new retirement village designed to put an emphasis on older people’s independence.

In line with government policies to prevent older people from losing their independence, and meeting the demand for sustainable and environmentally friendly buildings, the project comprises fully equipped apartments for independent older people in a building designed to be in keeping with its beautiful Mediterranean environment.

Retirement living 2.0: building and relocating

Keenly aware of the need to provide residents with a halfway option between private housing and an EPHAD care home, La Garde already had the Marie Curie residence, a public care home with 66 studio flats.

Over the years, this building on the outskirts of Toulon fell behind today’s standards of comfort and energy efficiency. The decision was made to construct a brand new building on another plot of public land nearer the town centre rather than undertaking the major repair and refurbishment work the home needed.

The project entailed a three-storey residential building of 3900 m² on a plot of over 6000 m². It would have 71 single studios and 4 double studios reserved for couples, all of which have a balcony. The project would also include common areas designed to create a friendly atmosphere between residents, such as a communal restaurant space and other areas required for the running of the home. A leafy outdoor area would provide a shared vegetable garden and a space for pets.

Designing a gold-standard building for a golden age

Appointed by Société Publique Locale (SPL) as the project manager, SAGEP was tasked with creating a sociable and friendly living space for independent older people in the local area.

The Chabanne Architectes et Ingénieurs firm’s concept was chosen by the project manager out of all the architectural proposals competing for selection. “The project is unique in that it takes an integrated approach to materials, energy efficiency and heavy use of renewable energies“.

This attitude underpins the whole project. Sustainable and natural solutions were chosen to reduce the building’s carbon footprint. The concrete on the facade was made using a low-carbon hydraulic binder, Ecocem GGBS. This method is fully compliant with the strictest environmental certifications in construction, as are the natural linoleum and the wood and aluminium composite joinery materials.

Working with trusted partners

Implementing these solutions in line with the Bâtiment Durable Méditerranée approach meant that bids to carry out work were restricted to local businesses known for the quality of their services, such as the Chaudronnerie Brignolaise, which was commissioned to erect the metal framework.

Chaudronnerie Brignolaise is Qualibat and RGE certified and had already proven its professionalism and high-quality work on a number of other regional construction projects, serving both the public and private sectors.

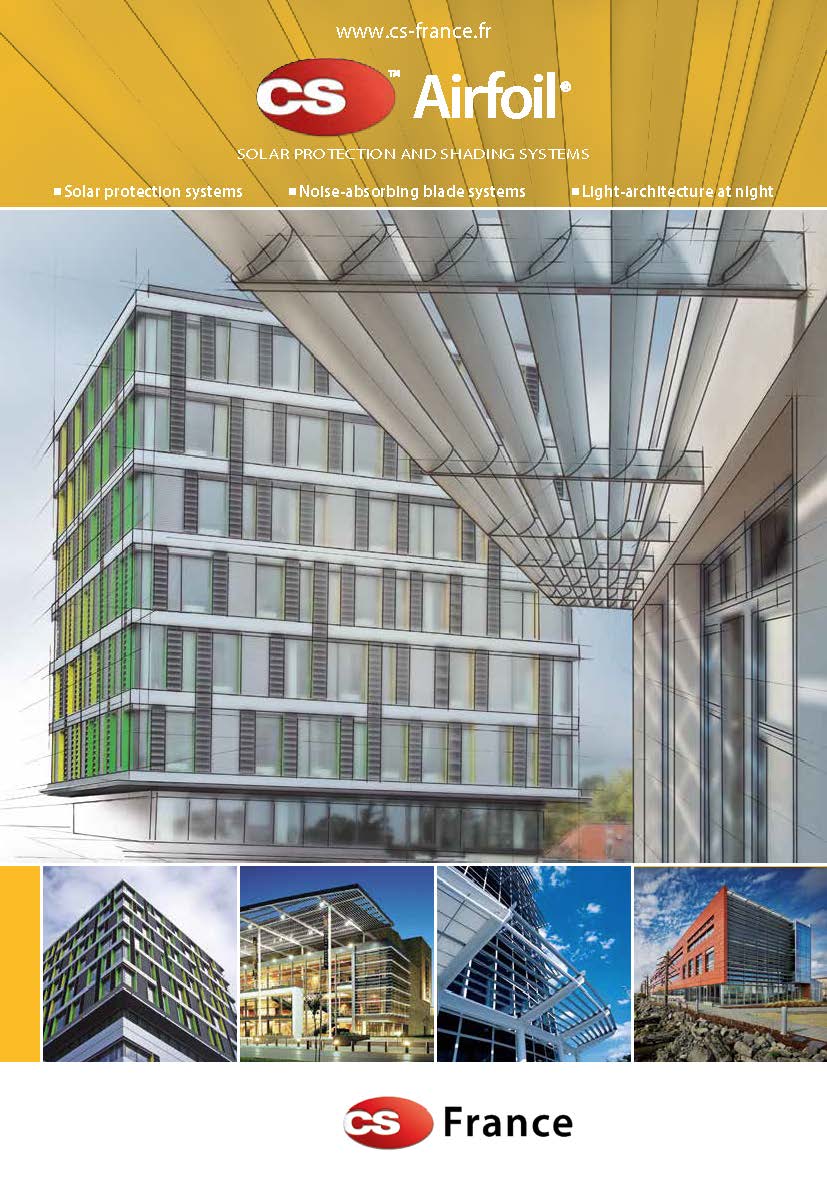

The firm also put forward a solution that met the project manager’s requirements, creating a metal structure for attaching fixed sun protection to the building, incorporating vertical and horizontal blades which make energy savings while bringing in fresh air and light. The sun protection blades surround the balconies and regulate excessive heat from direct sunlight at any time of the day.

Every step of the way!

Chaudronnerie Brignolaise once again trusted in Construction Specialties, with their Airfoil® brand sun protection, to manufacture the painted blades that would be suspended over the balconies, complying perfectly with the project’s specific needs.

The two companies have built a strong relationship over many years and projects. Airfoil® blades had already been used on various Chaudronnerie Brignolaise sites such as the EHPAD care home in Cogolin or the specialised care home in Saint Jean. As well as having worked together previously, Chaudronnerie Brignolaise also believed it was important to deal with a company that still makes its products in France. This means the supply chain is short and flexible, making delivery faster and more adaptable to the project’s specific needs.

The companies’ joint efforts and their desire to create bespoke solutions are illustrated on this project by the metal framework for the fixed sun protection. Chaudronnerie Brignolaise developed a bespoke tubular framework using all the latest metalworking equipment (a plasma cutting table, a hydraulic folding machine and a high-capacity punching machine). It was built specially to fit the U-shaped fixings that hold the Airfoil® blades together.

In total, over 2,822 linear metres of AFR 300 Airfoil® rectangular blades shield, and enliven, the building’s facade. These sun protection solutions were ordered in RAL 1002 – Sand Yellow, not only for the balconies but also the roof terraces. The aluminium is powder-coated in compliance with Qualicoat® requirements. This certification ensures that the powder coating of the products and components used pass a set of standardised tests. The coating will not crack or corrode on contact with air or moisture. The blades are fully UV resistant. Its colour will not fade and its shine will not diminish.

Why choose Airfoil® for this project?

Airfoil® blades also improve the quality of life for the building’s residents. The blades’ spacing is specially calculated and tested in a wind tunnel to limit the noise and effect of strong winds. User comfort is maintained even when the Mistral is blowing away.

Unrivalled recognition for providing maximum comfort to older people and local residents

At the end of its construction phase, Marie Curie 2 was awarded two certifications for its environmental quality. The low impact on its neighbours, its thorough waste management and its prioritising of eco-materials and local resources earned it a Habitat Environnement certification, and a Gold ranking from Bâtiment Durable Méditerranée.

The choice of biomass heating, a hydraulic earth-to-air heat exchanger and more than 500 m² of photovoltaic panels earned it the Bepos Effinergie 2013 certification, a shining example for positive energy buildings.